What Wood – MDF – So, at the risk of vilification by the entire boating community, I am going to talk about when to use MDF, or often Moisture Resistant MDF. I have heard so many people say that you can’t/shouldn’t use MDF on a boat, but frankly, these people don’t know what they are talking about. Don’t expect me to espouse this on a public forum anytime soon, but I will tell you a little bit about why and where you can (and trust me, it gets used a lot by the boating industry at large) use MDF and mrMDF on boats.

MDF and mrMDF are less resistant to water ingress and quickly become soft if allowed to get wet. It is not suitable for floors, though I have noticed a worrying trend in chip board subfloors and that is even worse! If you want to be extra safe, then avoid using it for walls and bulkheads. That said, much of the “wood” you see on narrowboats walls is typically veneered board and a relatively small proportion of that is veneered ply. That means the bulk of it is MDF with a thin veneer on top.

There is a wide range of veneered MDF readily available. In comparison, you will struggle to buy anything other than oak veneered ply, and this is 2–3 times the price. Veneered sheet material has been used in furniture making, including high-end furniture making (I have made some beautiful cocobolo drawers with veneer, you could never afford to do that in solid!) for a very long time. If the material is well sealed (e.g. spray lacquer on all faces) then water ingress in standard conditions, this includes boat interiors, shouldn’t be an issue. It shouldn’t be used for work tops or areas where it will have excess water exposure. Generally though, if your boat is so damp that MDF is falling apart as soon as looking at it, then you have bigger problems to worry about.

MDF or mrMDF

Veneered MDF with a hardwood lip allows you to make very attractive furniture at a lower cost than solid timber, while still building something that is going to last. It also allows you to hand select specific veneers and create your own materials. This is helpful where rarity/expense of timber (e.g. rosewood) or mechanical issues (e.g. slab doors) mean that you otherwise couldn’t produce what you want.

Where MDF, in this case mrMDF, comes into its own is for stability. It is a very homogenous material, so doesn’t warp or twist in the same way a solid wood or even plywood slab does. This means it is ideal for creating large slab doors. Once these are spray lacquered the change in moisture content will be almost zero, and they will not warp, twist, expand or contract.

If I am making slab doors (or even sometimes a faux shaker door) then I like mrMDF. I am not convinced that it is significantly more water-resistant than plain MDF, but it cuts and sands better, and it is much easier to paint. Regular MDF fluffs up as soon as paint touches it, meaning that multiple primer coats are required.

It’s easy to work, easy to shape, and it’s pretty cheap compared to other materials. It’s also much nicer than the all-pervasive chipboard we fill our homes with. Not only that, but it’s not solid wood, not even ply, but it has a time and a place

Pros

- Cheap

- Easy to work

- Very stable

- Comes in a wide range of pre-veneered boards

- Takes a paint finish well

Cons

- Not durable, if used incorrectly or not sealed it won’t last

- The dust from machining is unpleasant

- Considered a cheap, low grade material

- Softer than most woods and plywood so can dent more easily

- Not suitable for high wear areas

Enjoy more reading in these articles.

- Social Media Posts – Stories – Announcing this is unboxing

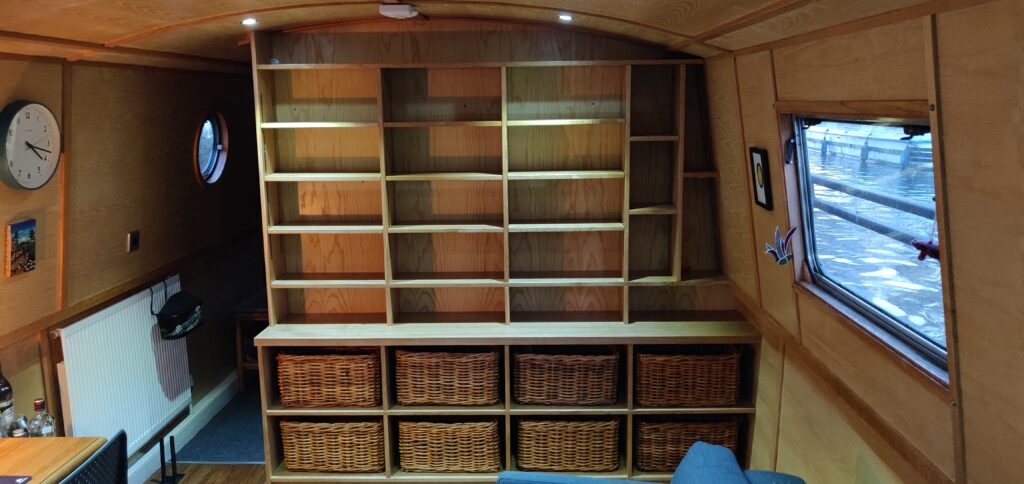

- S is for Shelves! See the best ideas

- W is for Wheelhouse, An Awesome and Remarkable Boat Part

- Towpath Talk – Characters of the Cut – January 2026

- New Year’s Sale: Celebrate with 20% Off Everything

- K is for Kitchens – What you need to Know